R&D

Technology Center - Strong R&D Engineering Department

| Number of R&D engineering personnel | 48 |

| Doctor | 2 |

| Master | 6 |

| Undergraduate | 21 |

| Junior College | 12 |

| Technicians | 7 |

| Professional | Motor |

| Electronic | |

| Automation | |

| Machinery | |

| Electrical | |

| Optoelectronics | |

| Material |

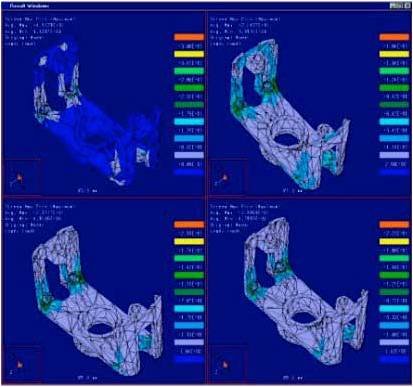

CNS unique design tool - finite element structural analysis

Structural: including static, model, buckling, contact, pre-compression and vibration analysis

Thermal: including heat transfer analysis and thermal design optimization

Power: including power and force analysis

Vibration: including dynamic time, frequency, random and impact analysis

Advantages of dynamic simulation

Optimize the use of materials

Reduce weight and cost

Reduce noise and vibration

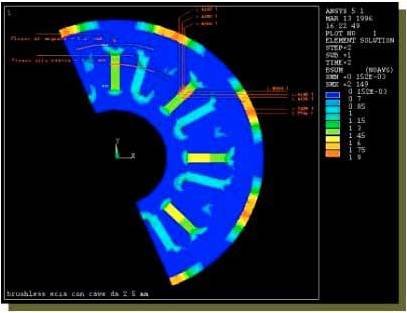

CNS proprietary design tool—Finite Element Magnetic Analysis

Advantages of designing motors this way

Optimize motor performance and efficiency

Optimize motor electromagnetic field distribution

Reduce motor vibration and noise

Significantly improve motor reliability

CNS’s technical cooperation and services to customers

Technical support

Training: products, usage, installation, software, procedures, solutions

patent

rapid prototyping template

Drive control

Reliability/Product Safety

Testing: Life, Noise, Noise and Full Performance Testing

Product Development Platform-Standard and Universal Development Guidelines

Based on the standard series

Based on the principle of universality and interchangeability

Customized based on customer requirements

Product application development-product technology matching

Standard product selection based on customer requirements

Performance and installation size matching based on customer requirements

Drive control system matching based on customer requirements

Technical system integration-solve problems for customers

Provide partial or complete motor solutions for customers

Brushless DC motor

Control System

Transmission mechanism (gearbox)