We Always Focus On Brushless DC motor, Brushless fan motor

Low vibration, high torque, low temperature rise, and long life give each motor a long-lasting combat effectiveness

The core materials use well-known brands such as Japan’s NSK bearings and Japan’s Mitsubishi IPM modules to ensure the continuous and stable operation of the motor from the source.

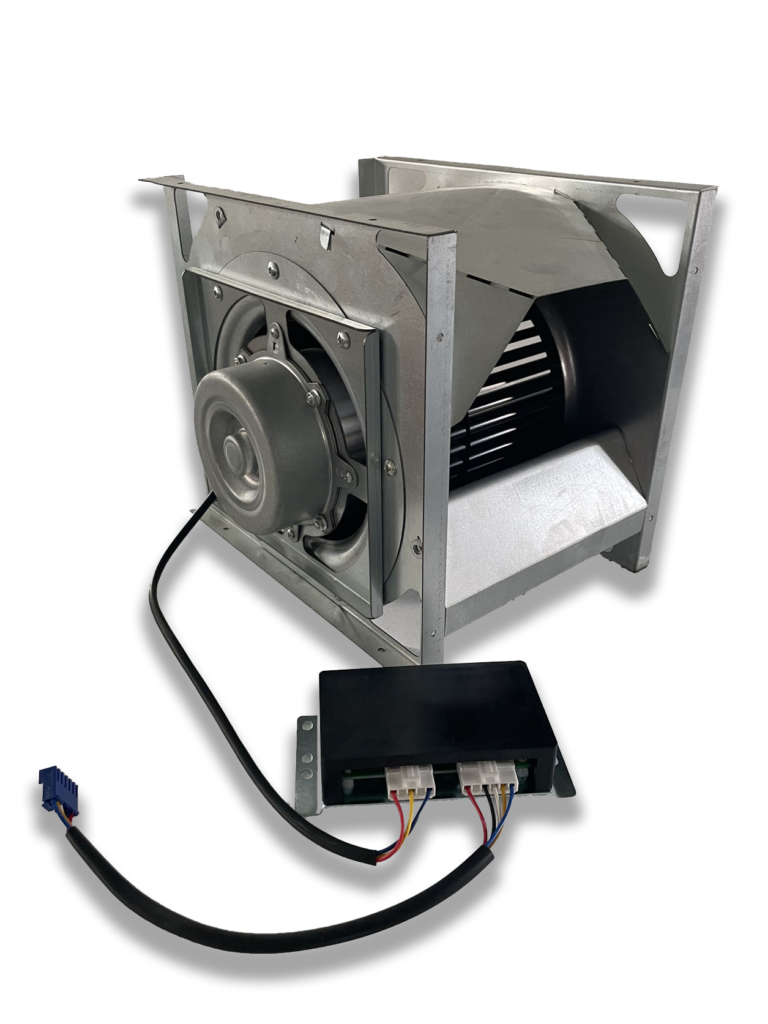

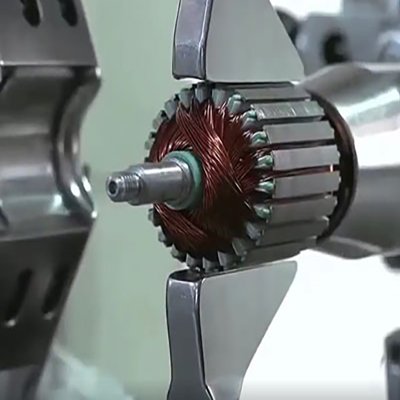

Imported original winding machines, customized molds, and paint-coated rotors are used to reduce noise, ensure high consistency of electrical characteristics, and product stability.

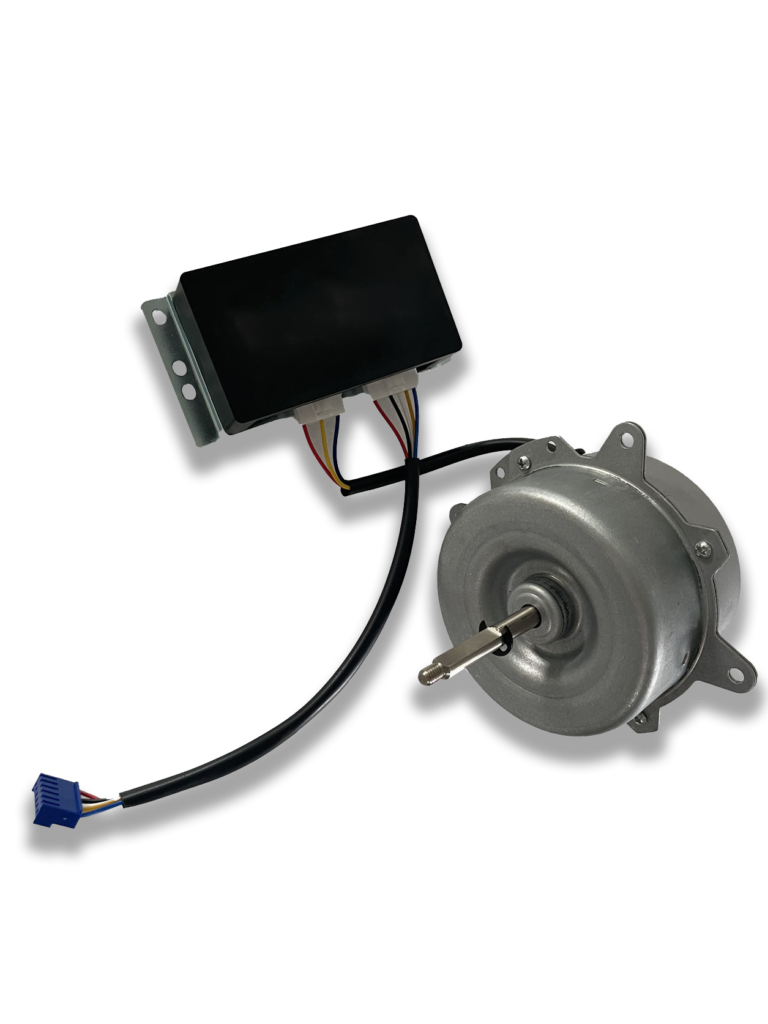

It has a full line of production equipment such as contact three-dimensional, ring gear precision testers, torque testers, high and low temperature testing equipment, etc.

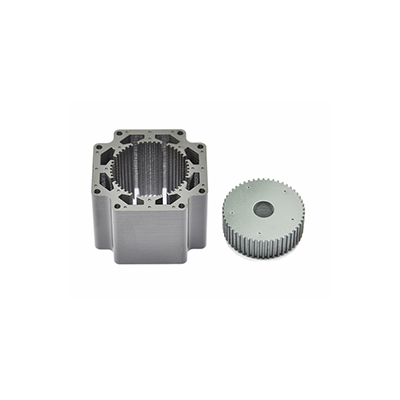

Aluminum covers and aluminum end caps dissipate heat quickly. All motors have been tested in a silent room to ensure low noise, low temperature rise and long service life.

Use three-dimensional coordinate instruments, torque diagrams, etc. to accurately measure motor accuracy and reduce losses, so that the motor can drive objects to operate stably.

It has a complete set of testing equipment such as arc minute test equipment, motor automatic test platform, high-precision oscilloscope, and driver test platform.

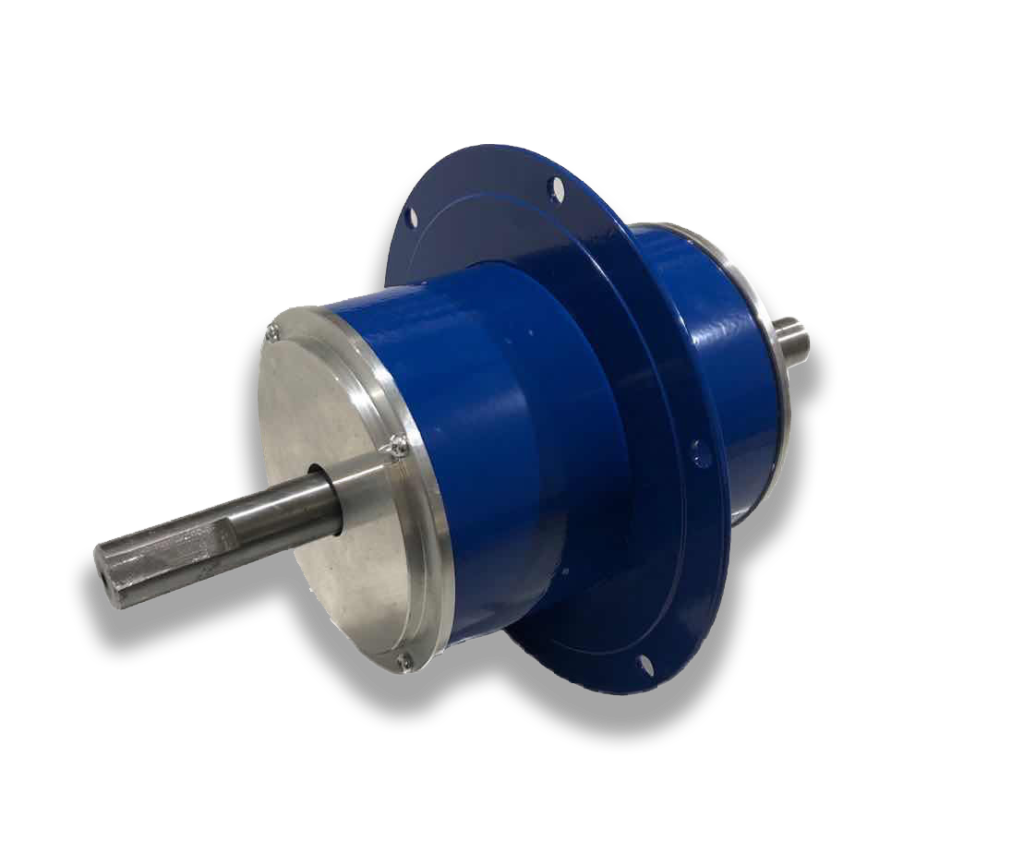

We have provided motor customization services for over 138+ industries

Our extensive experience and expertise in motor customization. By serving so many industries, we are able to meet diverse customer needs and solve a variety of complex technical challenges.